Assembly is as follows:

Put some Castor oil or light grease in the ball groove of the

outer ring and put in 8 of the 9 balls. Then slide the outer ring with the balls

from the front of the shaft to the ball groove in the crankshaft and bring the

ring into position.

|

|

|

|

| lightly grease the groove | Place the 8 balls in the outer ring | Gently slide the outer ring with the balls over the shaft |

Then push the last ball from the back side in the grooves and separate the balls so the ring cannot fall off. Since all this hand work will have brought some dirt in the system, spin the ball race without cage in a cleaning fluid.

|

a |

| Push the last ball in position | Spin the ball race without cage in a cleaning fluid |

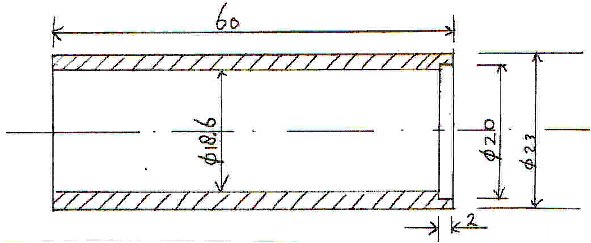

Then separate the balls until they have equal mutual distances (maybe with help of some Castor oil so they stay a bit in place) and press the cage in position with a tube (internal diameter 20 mm outer diameter 23 mm) that centers on the shaft, see drawing fig.5. Check if you still have 9 balls!. Then clean again and lubricate.

|

|

Separate the balls until they have equal |

Press the cage in position with a tube. |

Material : PVC or Tufnol.

Clean the case carefully, especially the bearing seats and heat

it up to appr. 100 degrees C, the same way as described above, and drop the

shaft + bearing into it.

Put in the shims and quickly the front bearing. Screw in the

clamping ring tight so the front bearing is in its proper position and finally

(when the crankcase is still at 80 degrees C or more) gently (plastic

hammer) the shaft forward; it may have been pushed a bit backward during the

mounting of the front race.

Now the shaft, with a propeller tightened, should show an axial play of 0.04

– 0.08 mm. If so, unscrew the clamp ring, put a bit of (weak) Loctite

on the thread and tighten it again.

|

|

| Heating up of crankcase | Drop the shaft + bearing into hot case |

|

|

| Installing the Shims |