MBPROFI 2003

This is a short note to give some assistance in running and

maintaining your MBPROFI pylon racing engine, as a follow-up of the running

instructions of February 2001, which concerned the MB40 Rear Intake engines

produced between 1998 and 2002.

This instruction is for the production series of the MBPROFI Front Intake engine

delivered after October 2002.

You may read things that you knew already for a long time. Don’t worry

about this: the information is also meant for the less experienced.

If your approach differs from ours, follow your own ideas and let me know the

results; I would be most happy to learn and develop further with your help!

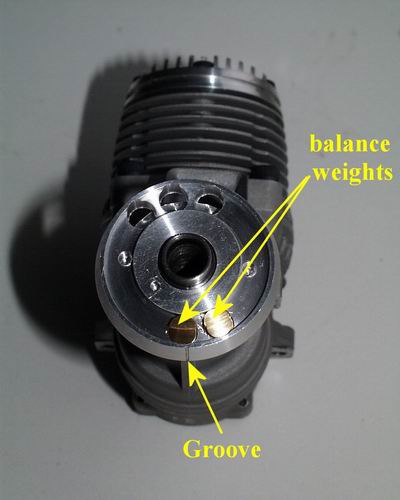

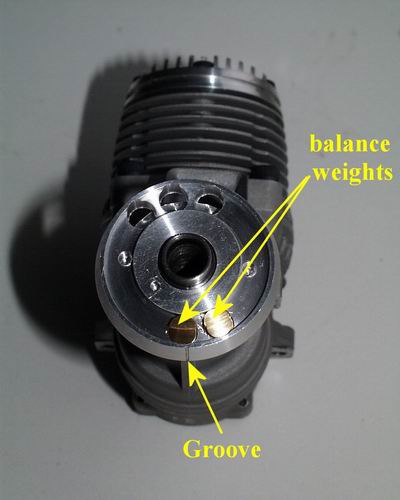

1.. BALANCING

As you can see in the engine, great care has been given to balance

the reciprocating masses of the piston /connecting rod and the valve opening

in the crankshaft. This is done in the crank-web by its shape and 3 tungsten-copper

counterbalance weights and in the spinner by holes and brass counter balance

weights.

Therefore it is necessary that the spinner is set in a specific position. At

the side of the spinner-backplate , near where the brass weights are, a small

groove can be seen. This groove should be in line with the crank pin or in other

words: if the piston is in top position, the groove should be also in top position.

Maybe easier is, that if the piston is pushed down (e.g. by a plastic pin through

the glow plug hole), the groove should also be in bottom position.

Be aware that this positioning of the prop-driver (within plus or minus 10 degrees)

is essential for proper running of the engine. This optimal balancing is supposed

to be one of the main features of the engine!

a |

| If the piston is pushed down, the groove should also be in bottom position |